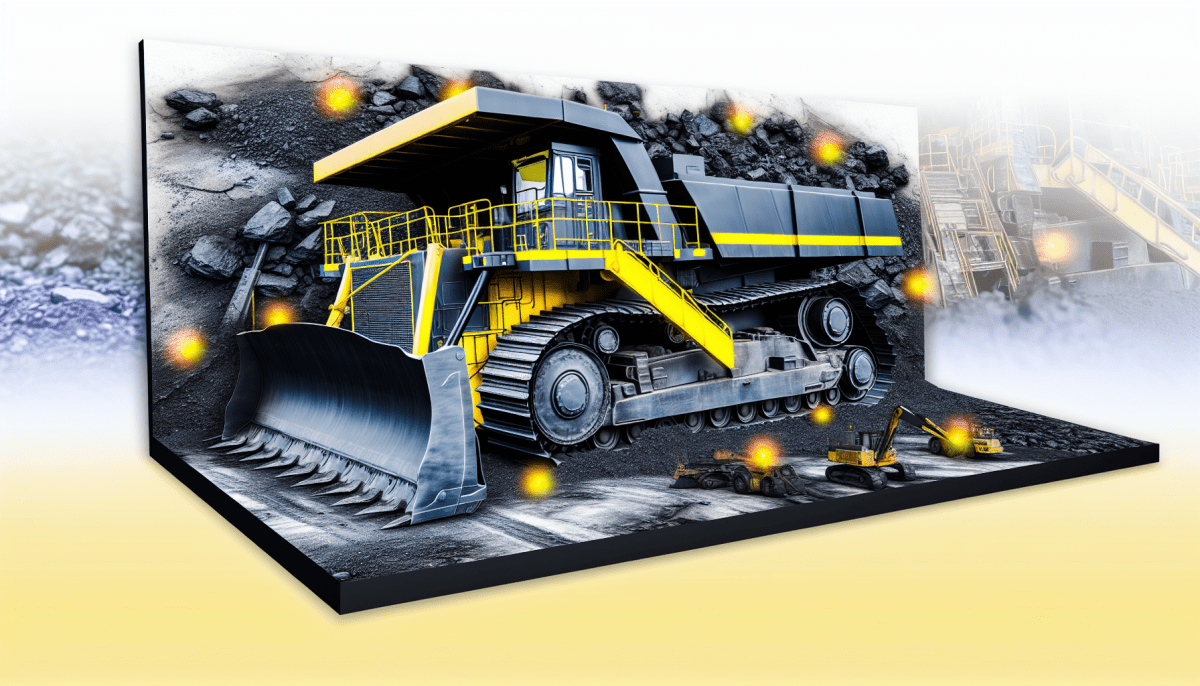

When it comes to coal mining machines, having the right equipment can make all the difference in achieving efficiency and productivity. One of the essential tools in the coal mining industry is the continuous miner. This powerful machine operates by cutting and gathering material simultaneously, allowing for a smoother and more efficient mining process. With its advanced design and technology, the continuous miner can navigate tight spaces and steep surfaces, making it ideal for underground mining operations.

Another vital piece of equipment is the shuttle car. These vehicles transport mined coal from the continuous miner to the main loading area. Shuttle cars come equipped with high-capacity dumpers and can operate seamlessly alongside continuous miners to help maintain a steady flow of materials. By optimizing the transport of extracted coal, shuttle cars significantly reduce downtime and enhance the overall efficiency of coal mining machines.

Additionally, roof bolters play a crucial role in ensuring safety while mining. These machines install steel bolts into the roof of the mine to prevent collapses and provide support for the working area. Investing in reliable roof bolters not only protects miners but also allows for more extensive operations without the risk of dangerous cave-ins. This safety equipment is just as essential as the extraction machines themselves, highlighting the importance of a well-rounded approach to choosing coal mining machines.

Lastly, proper maintenance equipment, such as hydraulic jacks and impact wrenches, enhances the longevity and reliability of coal mining machines. Regular maintenance ensures that all machines operate at peak efficiency, reducing the risk of breakdowns and costly repairs. By incorporating these maintenance tools into daily operations, mining companies can keep their coal mining machines functioning smoothly, ultimately boosting productivity and profitability.

Safety Practices in Coal Mining Operations

Firstly, regular training sessions are essential for all employees. Miners should receive thorough instruction on how to operate coal mining machines safely and efficiently. This training includes understanding emergency procedures and recognizing potential hazards in their work environment. By keeping every worker informed and prepared, the chances of accidents can significantly decrease.

Another vital aspect of safety in coal mining is equipment maintenance. Regular checks and servicing of coal mining machines help identify potential issues before they lead to accidents. Companies should schedule routine inspections and encourage workers to report any irregularities promptly. Keeping machinery in top condition not only improves performance but also safeguards the lives of those operating it.

Additionally, personal protective equipment (PPE) plays a significant role in maintaining safety standards. Miners must wear appropriate gear, including helmets, gloves, and respirators, to shield themselves from the various dangers present underground. By ensuring that all personnel adhere to PPE guidelines, companies can create a safer working atmosphere where the risk of injury is minimized.

Maintenance Tips for Mining Machines

When it comes to keeping coal mining machines in optimal working condition, regular maintenance is key. These heavy-duty machines operate in tough environments, making them susceptible to wear and tear. By following some simple maintenance tips, you can extend the lifespan of your equipment and ensure smooth operations.

First and foremost, always check the fluid levels in your coal mining machines. This includes hydraulic fluid, oil, and coolant. Low fluid levels can lead to overheating and mechanical failure. It's a good practice to conduct these checks daily before operations begin. Additionally, keep an eye out for any leaks, as they can point to potential issues that need addressing.

Cleaning your coal mining machines regularly is another crucial maintenance step. Dust, dirt, and debris can accumulate and affect the performance of your equipment. Make sure to clean filters, air intakes, and undercarriages. Regular cleaning not only improves efficiency but also helps in identifying any emerging problems early on.

Lastly, don’t forget the importance of proper lubrication. Many moving parts in coal mining machines require regular lubrication to function effectively. Refer to the manufacturer's guidelines for specific lubrication points and intervals. Using the right type of grease and oil will ensure that your machines run smoothly and help prevent costly breakdowns.

Future Trends in Coal Mining Technology

The future of coal mining technology is poised for exciting advancements that promise to enhance efficiency and safety. One of the most significant trends is the integration of automation in coal mining machines. These smart machines can operate autonomously, reducing the need for human intervention. This shift not only minimizes labor costs but also mitigates risks associated with worker safety in hazardous environments.

Another emerging trend is the implementation of artificial intelligence and machine learning in coal mining operations. By analyzing vast amounts of data, these technologies can optimize the performance of coal mining machines and predict equipment failures before they happen. This predictive maintenance can lead to less downtime and more reliable operations, ultimately boosting productivity.

Sustainability is also at the forefront of future coal mining innovations. Companies are now focusing on developing greener coal mining machines that reduce environmental impacts. Technologies such as carbon capture and storage are making their way into mining practices, aiming to minimize the carbon footprint associated with coal extraction. This shift is essential as the industry adapts to increased environmental regulations and public scrutiny.

Additionally, advancements in remote monitoring technology are revolutionizing how coal mining machines are managed. Operators can now oversee operations from afar, adjusting settings and monitoring performance in real-time. This capability not only improves operational efficiency but also allows for better decision-making, ensuring that coal mining processes are executed smoothly and effectively.