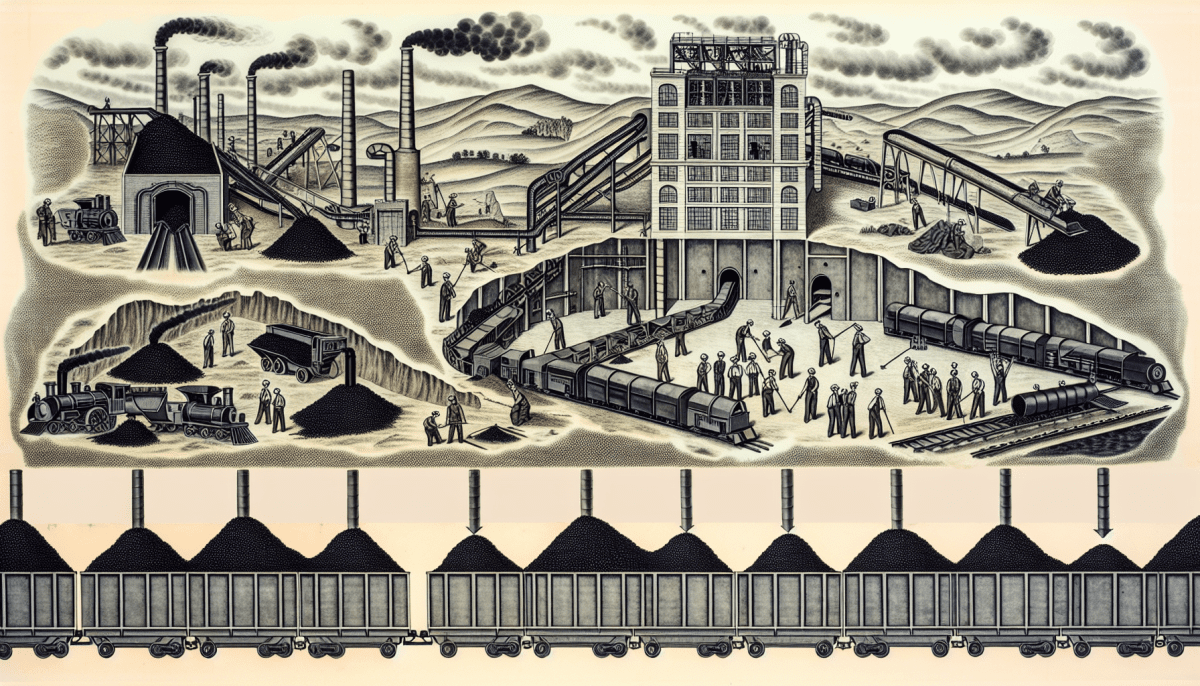

Coal preparation plants play a crucial role in the overall coal supply chain, ensuring that the coal extracted from mines is of the best quality before it reaches power plants and industries. One of the key functions of a coal preparation plant is the removal of impurities. This includes the elimination of non-coal materials such as ash, rock, and sulfur, which can adversely affect combustion efficiency and emissions. By separating these impurities, the coal becomes cleaner and more efficient for use.

Another essential function of a coal preparation plant is the sizing and classification of coal. During this process, the coal is crushed into smaller pieces, allowing it to be screened and sorted based on size. This sizing is important because different applications require specific coal sizes to ensure effective combustion and reduce waste. By accurately grading the coal, preparation plants help optimize its use in various industrial processes.

Moreover, a coal preparation plant often incorporates washing and flotation processes to further enhance coal quality. Washing uses water to remove impurities, while flotation utilizes chemical processes to detach valuable coal from undesired materials. These processes not only improve the coal's purity but also increase its market value. The result is a higher quality product that meets the stringent requirements of today’s energy market.

Lastly, coal preparation plants are equipped with advanced technological methods for monitoring and maintaining operational efficiency. Regular testing and analysis ensure that the processes remain effective and that the output coal consistently meets quality standards. This monitoring is vital for minimizing environmental impact and ensuring compliance with regulations, thereby making coal preparation plants essential for sustainable coal production.

Major Processes in Coal Preparation

Coal preparation plants are essential for improving the quality of coal before it is used in energy production and other applications. The major processes within a coal preparation plant can significantly impact the efficiency and effectiveness of coal usage. These processes aim to remove impurities, enhance the energy content, and prepare the coal for transportation and sale.

One of the first steps in a coal preparation plant is crushing. This process involves breaking down large chunks of coal into smaller, more manageable sizes. By crushing the coal, it becomes easier to handle and allows for more efficient separation of impurities in subsequent processes. After crushing, the coal typically undergoes screening, where it is sorted based on size. This ensures that only the right particle sizes proceed to the next steps, enhancing the overall process flow.

Following crushing and screening, the coal preparation plant employs washing to remove contaminants like dirt, rocks, and sulfur. The washing process typically involves a combination of water and specialized chemicals, which helps to separate the unwanted materials from the clean coal. This crucial step not only improves the quality of the coal but also reduces its environmental impact when burned.

Another significant process in coal preparation is floating and sinking, also known as density separation. This method relies on the differences in density between coal and other materials. By using water and various gravity-based techniques, the coal can be separated from impurities, resulting in a higher-grade product. Throughout these processes, continuous monitoring and control are essential to ensure the efficiency of the operations and the quality of the final product.

Importance of Quality Control

Quality control is a crucial component in the operation of a coal preparation plant. By ensuring that all aspects of the coal preparation process meet specified standards, quality control helps to maximize the efficiency and effectiveness of the plant. This not only enhances the quality of the final product but also minimizes waste and reduces operational costs. A well-managed coal preparation plant can significantly increase profitability by maintaining high-quality output consistently.

One of the primary goals of quality control in a coal preparation plant is to monitor the raw materials and the processes that transform them. Regular testing and inspections help identify any deviations from the desired quality standards. These inspections can catch problems early, allowing for timely interventions that can prevent higher costs and larger issues down the line. By implementing strict quality control measures, operators can ensure that the coal meets customer specifications, thereby fostering trust and long-term relationships with clients.

Additionally, quality control in a coal preparation plant helps protect the environment. A plant that prioritizes quality control is less likely to produce excessive waste or pollutants. This is especially important in today's world, where regulations concerning environmental impact are increasingly stringent. By focusing on quality, coal preparation plants can produce cleaner coal, which supports sustainability efforts and compliance with environmental laws.

Finally, the emphasis on quality control fosters a culture of excellence within the coal preparation plant. When employees understand the importance of their roles in maintaining quality, they are more likely to take pride in their work and strive for continuous improvement. This not only boosts employee morale but also leads to better teamwork and overall performance. Investing in quality control is, therefore, an investment in the people and processes that drive the success of the coal preparation plant.

Future Trends in Coal Preparation

The coal preparation plant is evolving as technology and environmental considerations reshape the industry. One of the most significant future trends is the integration of automation and advanced technologies. Automated systems can streamline operations, reduce human error, and enhance efficiency. With the rise of artificial intelligence and machine learning, coal preparation plants are likely to adopt these technologies for better resource management and predictive maintenance. This shift will make the processing of coal more effective and cost-efficient.

Another emerging trend is the growing emphasis on sustainability and environmental regulations. As climate change becomes a more pressing issue, coal preparation plants will need to adopt cleaner technologies. Innovations such as carbon capture and storage (CCS) are on the horizon, allowing these facilities to reduce emissions significantly. Additionally, there's a push for recycling and reusing water in coal processing, which can help minimize the environmental footprint of a coal preparation plant.

Furthermore, the global demand for metallurgical coal, particularly from countries like India and China, is expected to influence how coal preparation plants operate. These facilities will need to adapt their processes to meet the specific requirements of international markets. Improved beneficiation techniques will likely emerge to produce higher quality coal that can compete in the global arena, solidifying the role of coal preparation plants in the supply chain.

Lastly, the shift towards digital transformation is reshaping the coal industry. The adoption of data analytics in coal preparation plants can lead to informed decision-making and operational insights. As data from various stages of the coal preparation process is collected and analyzed, plant operators will be able to optimize production rates and reduce waste. Embracing these digital tools will be crucial for coal preparation plants looking to stay competitive in an ever-evolving market.